Polished concrete floors are becoming increasingly popular for those looking to add a modern, sophisticated look and feel to their home or business. The first step for polishing your concrete floor is preparation. You must thoroughly clean the surface before beginning work. Use a diamond grinder with coarse-grit pads to remove imperfections from the concrete surface. This will give you a smooth base layer ready for sealing. Knowing the best techniques for polishing concrete is important to achieve the desired result. In this article, we will share some expert tips on how to polish concrete floors like a pro!

Preparation for Polishing

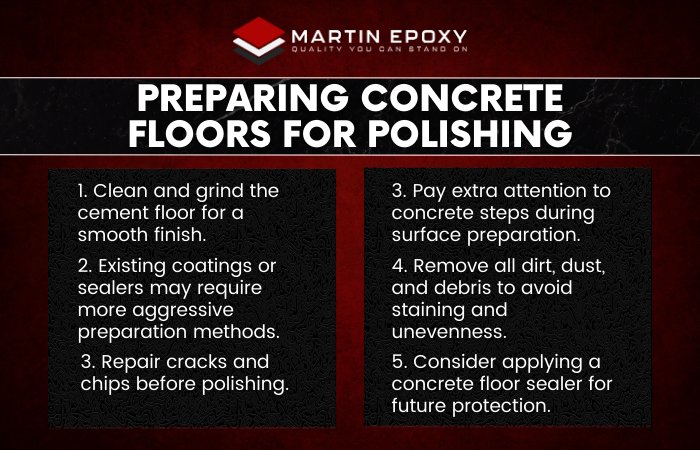

The surface must be properly prepared before you polish concrete floors. This involves thoroughly cleaning and grinding the cement floor to ensure a smooth finish. Preparing a concrete floor for polishing will depend on its condition.

- If there are existing coatings or sealers, it may require more aggressive preparation methods, such as shot blasting.

- Any cracks or chips should also be repaired before beginning the polishing process.

- Extra attention must be paid to concrete steps when prepping the surfaces before polishing.

- Removing all dirt, dust, and debris from each step is essential to avoid staining and unevenness during polishing.

- After this initial preparation stage, a concrete floor sealer is recommended to protect against future wear and tear.

What are the Equipments Needed for Polish Concrete

The most common polishing method is using diamond abrasives and specialized machinery. This type of polishing creates a smooth, shiny finish without the need for waxing or sealants. The grinding process removes imperfections in the concrete, such as roughness, discoloration, pits, and other blemishes. To polish concrete floors safely and efficiently, you must have the right equipment to do the job.

- A concrete floor grinder is a must-have tool for achieving a smooth, even finish on the surface. This machine uses diamond abrasives to grind away any imperfections in the concrete and leave it with a sleek, polished look.

- Polishing pads are then used to further refine the surface by buffing out any remaining scratches or marks. These specialized pads come in different grits, so you can choose which works best for your project.

- Having proper dust collection systems on-site is essential when polishing concrete floors. Not only does this keep workers safe from hazardous particles, but it also helps maintain visibility as they work.

- Vacuum attachments should be attached to all grinding tools, such as the floor grinder and polishing pads, ensuring that any debris created during the process is collected and disposed of properly.

- Buffing pads are also necessary to achieve an extra glossy shine after polishing your concrete floor; these plush materials help bring out its natural beauty without leaving any residue or streaks.

Types of Abrasives and Their Usage

The right abrasive selection is essential for a great finish when polishing concrete floors. Concrete polishing abrasives come in various types and grits that range from very coarse to ultra-fine. When choosing an abrasive type, it’s important to consider the flooring material’s hardness and porosity. For softer surfaces, use medium or even fine-grade abrasives; while for harder surfaces, coarser grades are better choices.

In terms of selecting the appropriate level of grit when working on concrete floors, several options are available.

- Coarse grits such as 16 or 20 provide faster removal times but can create deep scratches if used improperly. Choose higher numbers, such as 50-100 or 200-500, to achieve finer results with fewer scratches, depending on your desired shine level.

- Ultra-fine grinders like 800 – 1500 are often employed when seeking super glossy finishes without leaving any imperfections.

Ultimately, it’s up to you to decide which combination of concrete floor abrasives best suits your project needs based on the materials used and desired outcome. With careful selection and practice comes perfect polish concrete!

Polish Concrete Floors Finishing Touches

Now that you have the right abrasives to polish concrete floors and understand how to use them, it’s time to tie up loose ends with some finishing touches. These last steps will add a beautiful shine and luster to your freshly polished flooring. Here are three essential techniques to consider:

- Buffing

This is done with a buffing machine using either steel wool or diamond-impregnated pads. This technique helps smooth out any scratches on the surface of the concrete and leaves an attractive glossy finish.

- Glossing

A gloss agent can be applied over the floor to add a sheen. Be sure not to go overboard, though, as too much gloss can slippery the floor.

- Sealing

Once you have achieved your desired level of polish concrete, sealers should be used liberally to protect against wear and tear from foot traffic and other activities. A good rule of thumb is if you want a matte finish, opt for a water-based sealer; alternatively, select a solvent-based sealer for more of a glossy effect. For added protection, consider applying two coats of polish sealer after buffing and glossing.

These finishing touches will help your newly polish concrete floor look its best!

3 Maintenance Tips for Polishing Concrete Floors

Maintaining concrete floors is essential for preserving their longevity and beauty. To keep them looking great, there are a few steps to take:

- Vacuum regularly —- Cleaning concrete floors regularly helps to remove dirt buildup that can cause damage over time.

- Mop weekly —- Mopping should be done at least once weekly or as soon as spills occur. This will help prevent staining and discoloration from happening.

- Spot clean spills immediately.

Additionally, applying sealant every two to three years protects your concrete floor from wear and tear. The type of sealant used may vary depending on the finish desired, so it’s best to consult with a professional or refer to the manufacturer’s instructions for specific recommendations.

The final step in properly maintaining concrete floors is the polishing technique—an ideal way to enhance shine while providing extra protection from everyday use. Diamond polishing pads should always be used when working with concrete surfaces because they provide superior results without causing harm. A common practice is starting with a coarse grit pad and then gradually moving up to finer levels until achieving the desired level of polish and glossiness.

Polish Concrete Conclusion

Preparation is key – you must ensure everything’s clean and ready before beginning work on a project. To polish concrete floors, you must have the right equipment and abrasives. You’ll achieve beautiful results that will last years with proper maintenance. This will help protect your investment and give them extra shine! Remember regular cleaning; this can keep your polish concrete floors looking new.

At Martin Epoxy, our certified team uses specialized materials and follows all the steps in polishing concrete floors. So don’t hesitate: take the time to get informed, contact us today.