Are you considering resurfacing your concrete driveway or sidewalk? You may have heard of seal coating and wondered if it’s the right choice for you. Seal coating is a popular option for restoring, protecting, and beautifying existing concrete surfaces – but can it be used over concrete?

The answer is yes! I’m here to provide expert insight into how this process works so that you can make an informed decision about whether or not seal coating is the best solution for your project. Now let’s dive in and look at what goes into putting down a seal coat over concrete.

What Is Seal Coating

Seal coating is a protective covering applied to concrete flooring. It’s also known as a seal coat or concrete driveway sealing. This type of coating forms an effective barrier that repels water, oil, and other liquids while creating a smooth surface for traffic. Seal coats are usually made up of acrylic polymers that come in several colors and textures.

They not only give the pavement a fresh look but also protect it from damage caused by ultraviolet sunlight, de-icing road salts, and other chemicals used in road maintenance operations. Concrete sealers provide superior protection against deterioration due to weathering, freeze/thaw cycles, salt, sand abrasion, and more.

In short, they offer maximum performance with minimal upkeep — making them ideal for busy roads and parking lots alike.

Benefits Of Seal Coating Concrete

Indeed, seal-coating concrete is an excellent way to protect the surface and add a durable coating that resists weathering. This type of protection offers several benefits for homeowners. One of the major advantages of using a seal coat on your concrete is its ability to provide long-term protection from the elements.

- Seal coats act as a barrier between water and air, helping prevent moisture from entering and causing damage over time. It helps create a slip-resistant surface which can be especially useful around pools or other wet areas where falls could occur without proper footing.

- Another benefit of seal coating is its ability to enrich the overall look and feel of your concrete floors. It adds color, texture, and shine while also extending the life of the material underneath.

- It can help maintain a more aesthetically pleasing appearance while increasing durability against all types of weather conditions, including high temperatures during summer months and cold winters in colder climates. Plus, with regular maintenance, you won’t have to worry about cracking or fading since these properties are already built into the sealant itself.

- Finally, applying a seal coat to existing concrete provides greater value when selling or leasing out property in comparison to simply replacing damaged patches or painting over affected areas. By investing in this option upfront, you can save money by preventing costly repairs down the road due to deterioration caused by environmental factors like rain or snowfall accumulation over time.

With these clear implications for protecting one’s investment, it’s no question why so many people choose sealing concrete floorings today! Preparing concrete facade for seal coating involves thorough cleaning and removing any debris present before application begins; both steps are necessary for optimal results from this process.

Preparation Of Concrete Surface For Seal Coating

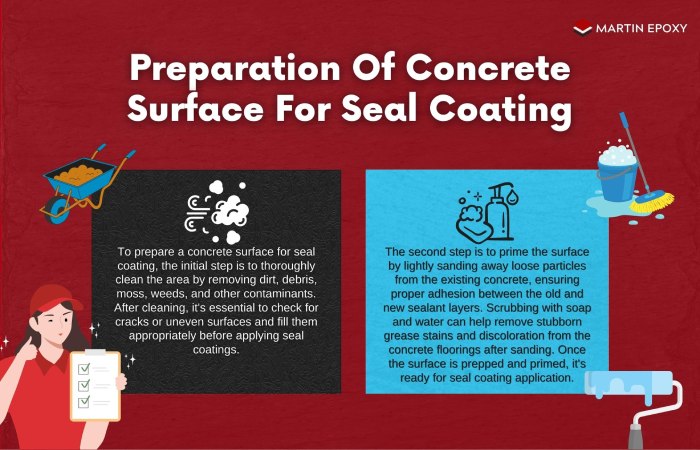

Preparing concrete facades for seal coating is an essential step in the resurfacing process. Proper preparation ensures a successful finish and the longevity of the project.

- The first step to take when preparing a concrete surface for seal coating is to thoroughly clean the area. This includes removing dirt, debris, moss, weeds, and any other contaminants that may be present on the concrete floorings. Once the area is clean, it’s important to check for any cracks or uneven surfaces in order to properly fill them before applying any seal coatings.

All holes should also be filled with either sand or cement-based filler material prior to sealing.

- The second step involves priming the surface by lightly sanding away loose particles from the existing concrete. This will ensure proper adhesion between the old and new layers of sealant. After sanding, scrubbing with soap and water can help remove stubborn grease stains and discoloration from the concrete floorings as well. Once the entire surface has been prepped and primed, it’s ready for the application of seal coatings.

Following these simple steps to prepare your concrete surface for seal coating you’ll ensure lasting protection against harsh weather conditions and extend its lifespan significantly.

Application Process For Seal Coating Concrete

Applying a seal coat to concrete is an important step in preserving the surface and extending its life. The process of seal coating concrete requires careful preparation, application, and maintenance. Here’s a closer look at the steps involved in applying the second coat to concrete facades:

- First, the surface must be properly prepared by thoroughly cleaning it with a pressure washer or other applicable equipment. It’s essential that all dirt, debris, oil stains, and any other contaminants are removed from the area before beginning the actual seal coat application process.

- Next comes the installation of the protective layer – this can involve spraying on liquid acrylic or asphalt-based products such as latex emulsion, coal tar epoxy flooring, or rubberized asphalt. Depending on the product chosen for your particular project, special tools may need to be used during this stage. This could include brushes, rollers, or squeegees. Once the material has been applied evenly over the entire surface, it should be left to dry completely before proceeding further.

- Finally, additional coats of sealer may need to be applied for optimal protection of your concrete floorings; this will depend upon factors like climate conditions and traffic volume. In cases where multiple layers are needed, each one should have ample time (24 hours typically) between applications to allow proper drying and curing of each respective coat.

Maintenance Tips For Seal-Coated Concrete

Maintaining a seal-coated concrete floor is essential to ensure the longevity of its beauty. To keep your newly sealed concrete looking amazing, you need to be aware of some key maintenance tips:

General Care and Maintenance:

- Regularly sweep or vacuum away any dirt, dust, or debris from the surface.

- Quickly clean up spills. This will prevent staining.

- Make sure that water drains properly from the surface after rain or snowfall.

- Avoid using harsh chemicals for cleaning purposes as they can eat away at the seal coat.

Seal Coat Repair Tips:

- In case of minor damage such as chipping, use an acrylic-based concrete patching material on the affected area.

- For more major repairs due to cracks and fissures in the cement, consider having a professional contractor come out and assess before attempting any DIY fixes.

Sealer Application Tips:

- Choose a weather window with no forecasted precipitation when applying penetrating sealers to existing surfaces; cool temperatures are best for avoiding evaporation problems during application.

- Clean off the entire space thoroughly prior to starting; this will help make sure there’s uniform coverage across all areas without any streaks or patches missing sealant protection.

- When resealing previously sealed outdoor spaces like driveways or patios, apply two coats instead of one for maximum durability against temperature changes and UV rays exposure over time.

Having knowledge about proper maintenance techniques for seal-coated concrete is important for keeping it looking great year-round – but what should you do if something does go wrong? The next section discusses troubleshooting problems with seal coating concrete.

Troubleshooting Problems With Seal Coating Concrete

Now that you know the basics of seal coating concrete, it’s important to understand how to troubleshoot any issues with your seal coat.

- To prevent a seal coating failure, inspect your surface for damage before applying the sealant. Inspect for cracks and other signs of wear and tear. If needed, repair any existing damage prior to applying the sealant.

- Afterward, ensure that all surfaces are clean and dry as this will help create an even application.

- If you’re having problems in a specific area or areas not taking on the sealant properly, try gently scrubbing the area with detergent mixed in warm water and then rinsing it off with cold water.

- This should remove any dirt or residue that may be preventing proper adhesion. If there is excess moisture or trapped air bubbles in your seal coat layer, use a hairdryer to blow out these pockets so they don’t affect the overall result of your project.

- Once your sealed concrete has cured completely (usually within 24 hours), check its condition again by doing another visual inspection and testing a small section with some water droplets – if no beads form on top of them, then you’ve successfully achieved an effective protective barrier against potential weather-related damages like freezing temperatures!

With regular maintenance inspections throughout the year and basic repairs when necessary, your newly sealed concrete can last for many years without needing additional work done to it.

Conclusion

Seal coating is a great option for protecting and enhancing the appearance of concrete floorings. Whether you’re looking to protect a driveway, patio, or another outdoor surface, a high-quality seal coat can offer significant benefits.

If you’re considering seal coating your concrete floorings, it’s important to work with a professional who has the knowledge, skills, and experience required to ensure a successful outcome. Martin Epoxy is an excellent choice for this task, with a proven track record of delivering high-quality seal coating services to customers throughout their service area.

By working with Martin Epoxy, you can enjoy the confidence that comes with understanding your concrete surfaces are in good hands. So why wait? Contact us at Martin Epoxy today to learn more about our seal coating services and get started on your next project!