Concrete dyeing is a great way to give your concrete surfaces a unique and dynamic look. From prepping the surface to mixing up the dye, there’s plenty of helpful advice for those wanting to learn more about working with concrete dye. Whether you’re looking for step-by-step instructions or just want tips on getting the best results out of your project, this guide has got you covered. So let’s get started – read on for everything you need to know about applying concrete dye like an expert.

What is Concrete Dye Exactly

Concrete dye is a type of coloring agent used to add color to concrete surfaces. It’s an easy and cost-effective way to enhance your existing or newly installed surfaces. Understanding what concrete dye works can help you decide if it’s right for you.

Concrete dye comprises finely ground pigments suspended in either water or solvent carriers. The pigment particles range from 1/1000th to 1/10th of the size of traditional cementitious paints, which means they penetrate deeper into concrete than regular paint. This makes them ideal for changing the color without affecting the texture or consistency of the surface beneath. Unlike stains, no surface preparation is needed before applying concrete dye as long as it’s applied on clean, dry concrete that hasn’t been previously sealed.

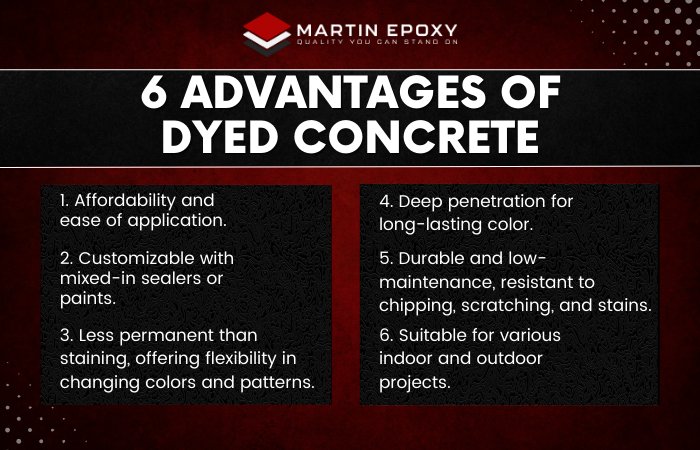

6 Advantages of Concrete Dye

Concrete dyeing has become increasingly popular for adding color and pattern to concrete surfaces. There are numerous advantages of using dyed concrete, starting with affordability and ease of application.

- Concrete dyes can easily be mixed into sealers or paints, allowing homeowners to customize their floors cost-effectively. With concrete dye, you don’t have to worry about damage to your existing floor.

- It’s less permanent than staining or other methods of coloring your floor. It also offers greater flexibility when changing colors and patterns than traditional stains that require extensive sanding and stripping before new coats can be applied.

- The dye penetrates deep into the surface, lasting longer than paint without quickly fading away.

- The durability of dyed concrete makes it an ideal choice for busy households looking for a low-maintenance floor solution.

- Unlike wood floorings which often need refinishing every few years, dyed concrete requires minimal upkeep and does not chip or scratch easily like tile or laminate.

- Additionally, colored concrete is far more stain resistant than regular cement, which helps protect against dirt buildup and discoloration from spills or foot traffic.

Dyed concrete provides all these benefits at a fraction of the cost compared to similar materials making it an attractive option for indoor projects such as kitchen countertops, bathrooms, patios, garages, etc. Its versatility allows it to work indoors and outdoors, giving homeowners plenty of design options while still being able to save money on labor costs by doing the project themselves with relative ease.

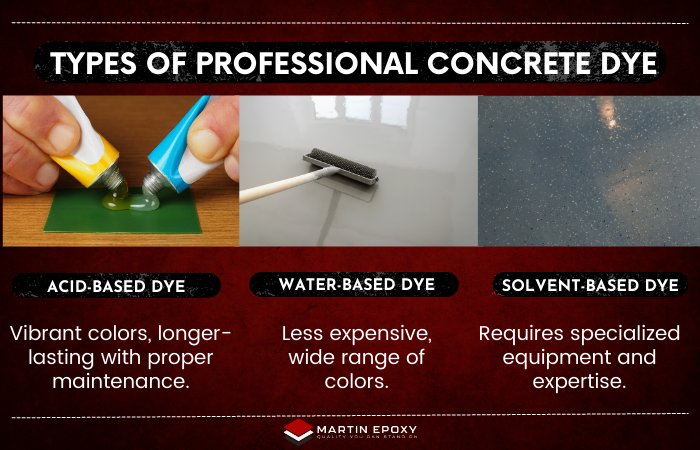

Types Of Concrete Dye

When it comes to professional concrete dyeing, there are several types of dyes available. Each type offers a variety of color options and application methods for achieving the desired look.

- Acid-based Concrete Dye: This dye is mixed with an acid solution and applied with either a roller or spray gun. The colors tend to be more vibrant than other types of dye and can last longer when properly maintained.

- Water-based Concrete Dye: This type of dye is mixed with water before being applied by brush, roller, or sprayer. It’s less expensive than acid-based dyes but may produce a less rich color range.

- Solvent-Based Concrete Dye: A solvent-dye mixture is used in this method, which requires specialized equipment and knowledge for mixing techniques that create the desired effect. It’s best left to experienced professionals who understand how to achieve optimal results with this dyeing process.

No matter what type you choose, proper preparation is essential for successful concrete dyeing projects. That means preparing the surface correctly before applying any products so you can get the most out of your efforts; otherwise, the results will need to be better!

Preparing the Surface for Dyed Concrete

The first step in applying a concrete dye is properly preparing the surface. Preparation is essential for ensuring that the dyed concrete looks great and lasts. To do this, follow these steps:

- Remove any dirt, dust, or debris from the surface with a broom or vacuum cleaner.

- Fill any cracks and repair damaged concrete areas before beginning.

- Use an etching agent like muriatic acid to create a rougher texture on the surface so that it absorbs more color when applied. Be sure to wear protective gear while doing this.

- After using the etchant, mix baking soda with water to neutralize it so it does not react with your dye later. Rinse off thoroughly after treating.

Once all of these steps are complete, you can be confident that your concrete surface is ready for the application of dyed concrete!

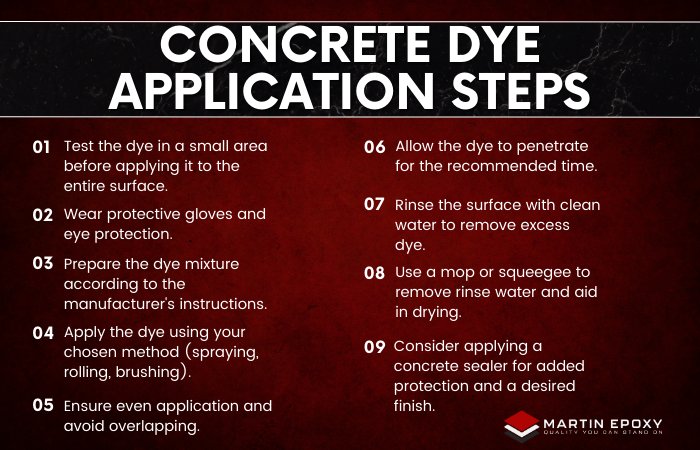

Application Of Dyed Concrete

Concrete dyeing is a relatively simple process that can be done in a few steps depending on the desired outcome and technique. Testing the dye in a small, inconspicuous area is recommended before applying the dye to the entire concrete surface. This will allow you to determine if the color and application method meet your expectations.

When applying either type of dye, use protective gloves and eye protection before starting.

- Prepare the dye mixture — Follow the manufacturer’s instructions to prepare the dye mixture. Typically, the dye is mixed with a solvent or water-based carrier solution. Ensure that you mix the dye thoroughly to achieve a consistent color.

- Apply the dye — Different application methods exist for concrete dye, spraying, rolling, brushing, or brushing. Choose the method that works best for your project. Start applying the dye from one corner of the concrete surface and work your way across. Ensure uniformity and avoid overlapping.

- Allow the dye to penetrate — Once you’ve applied the dye, let it penetrate the concrete surface. The specific amount of time required will depend on the type of dye and the manufacturer’s instructions. The dye typically takes several hours to penetrate and fully develop its true color.

- Rinse and clean —- After the dye has had sufficient time to penetrate, rinse the surface with clean water to remove any excess dye or residue. Use a mop or a squeegee to remove the rinse water and speed up the drying process.

Seal the concrete —- Consider applying a concrete sealer to protect the dyed concrete and enhance its longevity. Sealing the concrete will also deepen the color and provide a glossy or matte finish, depending on the type of sealer used. Follow the manufacturer’s instructions for the application of the sealer.

Maintenance and Care

Maintaining and caring for concrete dye ensure a vibrant, eye-catching surface. Here’s what you need to know:

- Cleaning concrete dye is an essential part of the maintenance process. Regularly sweep or vacuum away dirt and debris, which can dull its appearance over time.

- Preserving concrete dye requires protecting it from ultraviolet (UV) rays which can fade the color. Use sealers specifically for concrete dyes to guard against UV exposure and staining agents like water and oil.

- Caring for concrete dye also means avoiding harsh chemicals when cleaning it. Always use mild cleaners and detergents suitable for these types of surfaces.

Conclusion

When done properly, your freshly dyed concrete should be good to go! You’ll want to keep up with regular maintenance such as sweeping, vacuuming, sealing, and using gentle cleansers to preserve the beauty of your newly transformed space. And remember protection too – ensure you’re safeguarding your investment by applying appropriate sealants whenever necessary to enjoy its attractive outcomes for years to come!

At Martin Epoxy, our experienced team uses state-of-the-art equipment and follows concrete dye application to achieve durable results. Contact us to learn more about our services.