Concrete coating is an important part of any construction project, from driveways to industrial floors. They make the surface look great, protect it from wear and tear, and increase its lifespan significantly. But how long do cement coatings last?

Many people don’t know the answer to this question – after all, a wide variety of factors affect their durability. In this article, we’ll go over everything you need to know about how long this coating will last. Then, we’ll discuss these topics in detail so that you can lengthen the life of your concrete flooring.

Types of Concrete Coating

When it comes to concrete coating and staining, a variety of options are available. Epoxy coatings provide excellent resistance to chemical and environmental damage. This makes it ideal for use in areas that receive heavy wear or need protection from harsh weather conditions.

- Urethane coatings offer superior flexibility and impact resistance but may require more frequent maintenance than other coatings.

- Acrylic coatings are often used on interior surfaces due to their quick drying time, low odor, and cost-effectiveness.

- Polyurea coatings have an incredibly fast curing time and can be applied directly on moist surfaces without any primers or sealants before application.

- Lastly, polyaspartic coatings provide unparalleled durability, making them suitable for indoor and outdoor applications.

All these different coating solutions come with unique benefits that should be weighed when considering the best option for your project. Now let’s discuss the preparation and application process needed to ensure the maximum longevity of your concrete coating solution.

Preparation and Application Process

Preparation is key in determining the longevity of a concrete coating. It would help if you used proper surface preparation techniques to create an optimal environment for lasting success with any coating application. This includes removing dirt, dust, and debris from the surface and ensuring that no oils or other contaminants are present before beginning the process.

It may require additional steps, such as grinding down rough areas and filling in cracks before applying the coating. When it comes time to apply the actual layer, several methods are available depending on your project’s needs. Spraying is often used for larger surfaces because it provides quick coverage over large areas and allows you to achieve uniform thickness levels throughout the coated area.

Other options include:

- Roller applications can be done manually or using specialized equipment.

- Brush applications.

- Troweling when an extremely smooth finish is desired.

- Each method has advantages and disadvantages, so you must choose based on your requirements and preferences.

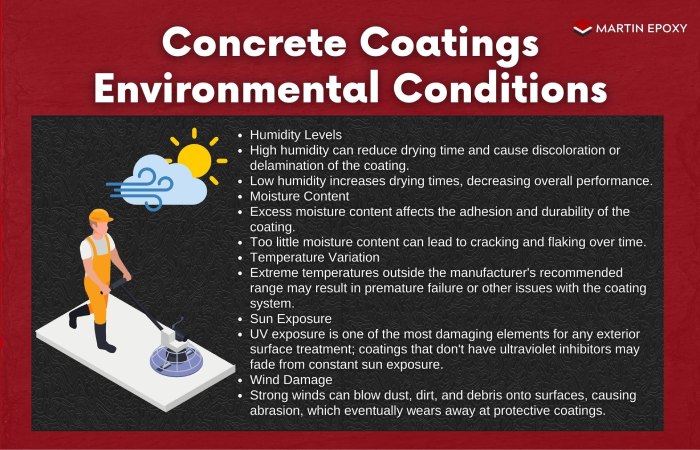

Concerning concrete coating, environmental conditions play a huge role in longevity. Here are the primary factors affecting how long your coating will last:

Regardless of the method you use, proper cleanup afterward is essential to maintain a high-quality finished product. This includes wiping away any excess material from tools or brushes and properly disposing of waste materials like solvents or cleaning agents used during the surface cleaning processes needed before starting the job itself.

Environmental Conditions

- Humidity Levels

- High humidity can reduce drying time and cause discoloration or delamination of the coating.

- Low humidity increases drying times, decreasing overall performance.

- Moisture Content

- Excess moisture content affects the adhesion and durability of the coating.

- Too little moisture content can lead to cracking and flaking over time.

- Temperature Variation

- Extreme temperatures outside of the manufacturer’s recommended range may result in premature failure or other issues with the coating system.

- Sun Exposure

- UV exposure is one of the most damaging elements for any exterior surface treatment; coatings that don’t have ultraviolet inhibitors may fade from constant sun exposure.

- Wind Damage

- Strong winds can blow dust, dirt, and debris onto surfaces, causing abrasion, which eventually wears away at protective coatings.

Considering all these variables during installation ensures you achieve longer life and performance out of your seal coating over concrete projects. Of course, proper maintenance and cleaning are also essential components – we’ll cover those topics next!

Maintenance and Cleaning

When it comes to concrete coating, maintenance, and cleaning are paramount. To ensure the longevity of your layers, you will need to develop a regular cleaning routine that suits your needs and preferences. The following table provides an analysis of what is involved in this process:

| Concrete Coating Maintenance | Regular Cleaning Routine | Cleaning Products Selection |

| Sweep or vacuum daily | Use mild detergent | Choose pH neutral product |

| Rinse with water | Apply sealer regularly | Avoid abrasive cleaners |

| Pressure wash | Spot clean as needed | Check for hazards |

In addition to the above steps, one should consider some preventative maintenance tips when dealing with concrete coatings.

- For instance, always make sure to pre-treat any stains before attempting to remove them using more aggressive techniques such as scrubbing or pressure washing.

- Be mindful of potential hazards like oil spills which can cause damage if not addressed promptly.

- Lastly, be sure to select appropriate cleaning products so as not to affect the integrity of the coating itself adversely.

Repair and Replacement

Concrete coating repair is an important part of ensuring your surface lasts as long as possible. If a crack or chip appears in the coating, it should be repaired quickly. Depending on the severity of the damage, you may need to replace the entire layer.

- When repairing concrete coatings, make sure you use materials compatible with the existing material. This will help ensure a proper seal and prevent further deterioration.

- You also want to avoid using harsh chemicals when cleaning up after repairs have been made so as not to cause additional wear and tear on the coating itself.

- Replacing concrete coatings can be more involved than simply patching up a few areas here and there; often, it requires completely removing all layers of old coating before laying down new ones.

- It is best to consult a professional to get expert advice on how best to approach such a project and what kind of materials would work best for your specific application. Professional installers know exactly which products will provide maximum protection against moisture, temperature changes, UV light exposure, and other factors that can lead to premature degradation over time.

With their assistance, you can ensure your concrete surfaces look great for many years! In addition to providing enhanced durability, replacing worn-out concrete coatings offers an opportunity to upgrade features like color or texture to reflect your style preferences better while providing superior performance benefits.

Benefits of Concrete Coating

The benefits of applying a concrete coating are numerous. It provides durable protection for the surface, making it more resistant to damage from liquids and abrasive materials. Furthermore, its slip-resistant surface makes walking on it much safer. You can improve the aesthetics of your property with a decorative coating or stamping technique that adds texture and color.

Using a concrete coating is cost-efficient as compared to replacing concrete surfaces regularly. This also extends the lifespan of your existing pavement considerably, saving both time and money in the long run.

Here’s what you get when you choose a concrete coating:

- Durable protection against wear & tear

- Slip-resistant surface for safety

- Improved aesthetics of your property

- Cost efficiency & extended lifespan

Concrete coatings offer many advantages over conventional methods of resurfacing or repairing damaged pavements–from improved durability to enhanced aesthetic appeal to greater cost savings in both time and money. All these factors make them an ideal choice for any homeowner looking for long-term solutions for their outdoor living spaces!

Conclusion

Concrete coatings are highly effective in protecting and improving your concrete surfaces. They can last many years with proper maintenance, preparation, and application process. With all the benefits of applying a concrete coating, it’s easy to see why so many people choose this option to spruce up their homes or business.

Investing in a high-quality epoxy coating is a smart choice if you want to protect your concrete surfaces for the long term. And when it comes to finding the right layer for your needs, Martin Epoxy is a company you can trust.

With our comprehensive experience in the industry and commitment to quality and customer satisfaction, Martin Epoxy offers a range of coatings and finishes that are designed to last. So whether you’re looking to protect your garage floor, commercial facility, or any other concrete surface, Martin Epoxy has the expertise and products you need.

So why wait? If you’re ready to give your concrete surfaces the protection they deserve, contact us at Martin Epoxy today to learn more about our products and services.